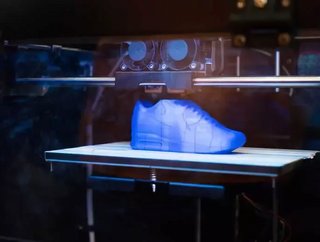

Stratasys launches its first UK training centre

The US-based 3D printing manufacturer, Stratasys, has unveiled its first authorised UK training centre and will be controlled by the company’s UK Platinum Partner, Tri-Tech 3D.

The site, which is named Tri-Tech 3D Print Academy, will provide high-level expertise and training for users of Stratasys FDM and PolyJet 3D printing technologies.

Stratasys aims to support its users in the most effective way possible in order to maximise their investment in 3D printing and help to eliminate expenses through production errors and material wastage.

“At Tri-Tech 3D, we have been working intimately with Stratasys additive manufacturing for over 10 years and have a deep expertise in its core technologies,” said Adrian Painter, Group Director of Tri-Tech 3D.

See more:

- Solukon partners with Siemens to unveil new 3D printing system

- Northvolt confirms partnership with BMW and Umicore

- BASF begins joint venture with Plug and Play to accelerate digital innovation in China

- Read the latest issue of Manufacturing Global here!

“We believe in the truly disruptive potential of additive manufacturing, however implementing it within traditional design and production environments without the appropriate training can be challenging. This is where we can add real value, supporting users and businesses small or large in becoming more efficient, productive and profitable through the effective use of additive manufacturing.”

It has been confirmed that a number of courses are available which offer participants the opportunity to enhance their knowledge of 3D printing and its use of design and production applications through a range of different key topics.

“We are delighted to have Tri-Tech 3D as our first authorised Stratasys Training Center in the UK,” commented Matthias Gukelberger, Vice President and Head of Services EMEA of Stratasys.

“It’s very important to us that we provide users of our technology the local expertise to guide them throughout their additive journey and Tri-Tech is the ideal partner to help us achieve this.”

- Markforged Among Firms Embracing Distributed ManufacturingDigital Factory

- Stratasys’ 3D printing journey & the impact on healthcareTechnology

- Replique, the secure 3D printing platform for manufacturersProcurement & Supply Chain

- EOS is leading sustainable manufacturing with 3D printingSustainability & ESG