BASF links up with Materialise to expand 3DP materials and software

3DP software and printing solutions business, Materialise, and chemicals giants, BASF, has announced a major collaboration which is set to improve the range of 3DP materials and software available for manufacturing.

German-based BASF will invest $25mn and focus on applications in the consumer goods sector as well as in the automotive and aviation industries.

Within the framework of an open business model, the two companies will join forces to continuously improve materials and software for various 3D printing technologies and bring them to the market at an increased rate.

“Our two companies’ business areas complement each other very well and our cooperation will put us in an even better position to find and develop new business opportunities,” said Volker Hammes, Managing Director of BASF 3D Printing Solutions GmbH.

“Together, we can exploit our strengths even better to advance the 3D printing sector through the development of new products and technologies together with our partners and our customers.”

This new venture allows BASF to carry out wider scale testing on the machines and within the infrastructure of Materialise.

See more:

- £50mn British Steel investment enhances wire rod business

- Unilever and Nestlé become first major processors to use ProductDNA

- UK government and Lockheed Martin to begin £38mn joint venture

- Read the latest issue of Manufacturing Global here

“To increase the adoption of 3D printing as a complementary manufacturing technology for final products, our industrial customers increasingly demand more control, more choice and ultimately lower cost,” says Fried Vancraen, Materialise CEO.

“We are confident that this collaboration with a leading manufacturer of materials will help to accelerate the adoption of 3D printing in existing vertical markets and create significant business opportunities in new markets.”

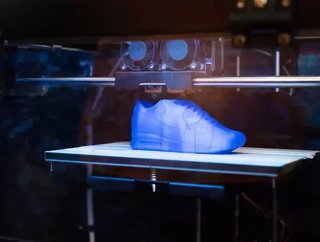

3D printing is a transformational technology that holds the potential to revolutionize entire industries by making it possible and cost-effective to mass manufacture entirely individualized products.

It also allows for design optimizations and functional improvements, such as lighter designs, that are impossible to create with standard manufacturing technologies.

This has seen an increasing number of industries, including the aerospace, automotive, footwear and the eyewear industry, utilise 3D printing to solve specific manufacturing challenges.

- Crowe UK: 2024 Manufacturing Outlook Report Explores GrowthProduction & Operations

- Top 10: Chief Manufacturing OfficersProduction & Operations

- Aerospace Insight: Where does Boeing make all of its PlanesProduction & Operations

- Comau's Automation Solutions for Outside of ManufacturingAI & Automation