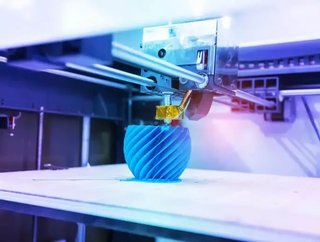

Stratasys partners with Solvay to produce new FDM materials

Israeli 3D printer manufacturer Stratasys has announced a partnership with Belgium’s advanced materials company Solvay.

The move comes as part of the launch of their authorized materials partner program, which seeks to expand the range of polymers available to manufacturers using Stratasys’ FDM 3D printers.

Rich Garrity, Stratasys’ President, Americas, said: “Stratasys is committed to expanding our portfolio of advanced, specialized materials for high performance FDM printers – enabling manufacturers to readily use 3D printing for production applications. By combining our expertise with Solvay, customers can make use of a broad range of high performance applications – all while maintaining the level of quality and reliability expected from Stratasys high-performance FDM consumables.”

SEE ALSO:

-

Protolabs and GE Additive use 3D printing technologies for Met Gala gowns

-

NASA grants $5.2mn contract to Auburn’s National Centre for 3D printing

As the first member of that program, Solvay will have access to tools and expertise from Stratasys to help develop polymer materials for use in its F900 3D printer.

“With this strategic partnership, we are combining Stratasys’ leadership in fused deposition modelling 3D printing with Solvay’s leadership in developing high-performance, AM-ready materials for the most demanding applications in a large number of industries,” said Christophe Schramm, Business Manager for Additive Manufacturing in Solvay’s Specialty Polymers Global Business Unit. “This is fully in line with Solvay’s ambition to push the limits of high-performance additive manufacturing.”

Though no information has been released on the specific materials they hope to develop, the F900 is an industry-ready printer that features the largest build size of any FDM machine.