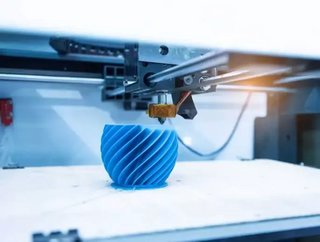

HP deems the US as the leader of additive manufacturing

According to a recent study conducted by A. T. Kearney, the consultancy firm, announced the US as the leader in additive manufacturing.

The study, which was commissioned by HP Inc, found that it terms of 3D printing adoption, the US ranked first, followed by Germany.

Korea placed third, with Japan fourth, and the UK fifth, based on “a country’s governance, capabilities, and economic assets support the adoption of 3D printing” the report reads.

3D printing dominated how the firms ranked the nations, accounting for 50% of the country’s total score.

SEE ALSO:

-

US Airforce launches additive manufacturing in supply chain initiative

-

Boeing and Assembrix to partner on additive manufacturing project

The following categories each made up 10% of the score: Trade, Governance, Demand, People, and Technology.

Singapore, Canada, Sweden, France, and Australia, were the remaining countries that ranked in the “Leaders” group, in that order.

The following groups were deemed “Challengers” – who still have the opportunity to capitalise on the industry – and “Followers” – who have just entered the sector.

China ranked number one in the Challengers category, placing it 11th overall, whilst Indonesia is leading the Followers, placing 21st in the total table.

The report also ranks the fastest growing markets for additive manufacturing, with South Korea ranking first, followed by Italy and the UK.

- Markforged Among Firms Embracing Distributed ManufacturingDigital Factory

- Replique, the secure 3D printing platform for manufacturersProcurement & Supply Chain

- EOS is leading sustainable manufacturing with 3D printingSustainability & ESG

- Next level 3D-Printing developed by the University of TokyoTechnology