BigRep launches first fully 3D printed and functional e-motorcycle

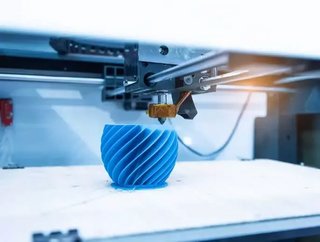

The additive manufacturing company, BigRep, has unveiled the world’s first fully 3D printed and functional e-motorcycle: The NERA e-motorcycle.

The prototypes, created by NOWlab, is set to see a whole new dimension for 3D printing explored with all the NERA parts being 3D printed, with the exception of electrical components.

Stephan Beyer, PhD, CEO of BigRep GmbH, said: “These exciting prototypes not only demonstrate the unprecedented capacity of FFF large-scale 3D printing technology in Additive Manufacturing. They also emphasize our unique ability as the market’s innovation and thought leader to bring cutting-edge technologies from design to reality, providing an added-value market lead for our industrial customers.”

See more:

- Volkswagen reaches 30mn milestone in deliveries in China

- Piramal Glass deploys Microsoft Azure within its manufacturing operations

- BASF and the GAC R&D Centre collaborate to introduce electric concept cars in China

- Read the latest issue of Manufacturing Global here!

There are a number of benefits that 3D printing provides such as the production of end-use parts, by decreasing lead times and costs, as well as optimising supply chains and limiting dependency on supplier networks.

Daniel Büning, co-founder and Managing Director of NOWlab, said: “The NERA combines several innovations developed by NOWlab, such as the airless tire, functional integration and embedded sensor technology. This bike and our other prototypes push the limits of engineering creativity and will reshape AM technology as we know it.”

As the developer of the world’s largest serial production 3D printers, Big Rep is prioritising setting standards in speed, reliability and efficiency.