Nike reveals sustainable manufacturing achievements

Nike has released its FY14/15 Sustainable Business Report, which details the progress it has made against environmental and social targets, as well as its low-carbon plans for the future.

The company’s ultimate goal is to double its business while halving its environmental impact.

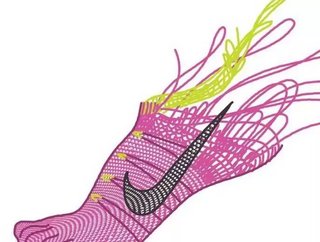

Achievements so far include a sustainable overhaul of its manufacturing processes, including using Flyknit technology, which produces 60 percent less waste than traditional cut-and-sew methods. Since 2012, the technology has reduced nearly 3.5 million pounds of waste.

In addition, Nike has been using plastic bottles to convert into recycled polysetser and, since 2010, more than three billion bottles have been diverted from landfills. The company’s ColorDry technology, which dyes fabric using zero water, has saved more than 20 million litres of water.

The company is also working on reducing the amount of energy used to produce its footwear – it takes about half the energy and generates around half the emissions to make Nike shoes as it did eight years ago. Looking to FY25, Nike aims to use 100 percent renewable energy in its owned and operated facilities, and has already implemented on-site renewable energy generation at some of its largest facilities.

Nike also revealed its targets for 2020, which include:

- to have zero waste from contracted footwear manufacturing sent to landfill or incineration without energy recovery

- to source 100 percent of products from contract factories meeting the company’s definition of sustainable

- to create products that deliver maximum performance with minimum impact, seeking a 10 percent reduction in the average environmental footprint and an increased use of more sustainable materials overall

- by the end of 2025, to reach 100 percent renewable energy in owned or operated facilities and to encourage broader adoption of renewable energy as part of an effort to control absolute emissions.

Follow @ManufacturingGL

- Honeywell's Hydrogen Journey to Net Zero ManufacturingSustainability & ESG

- Lean Manufacturing & Data Action with Schneider ElectricLean Manufacturing

- Aggreko: Navigating ESG Challenges in ManufacturingSustainability & ESG

- Toyota's Integrated Report 2023: Focus on ManufacturingLean Manufacturing