UK government to finance £24mn into aerospace projects with Industrial Strategy

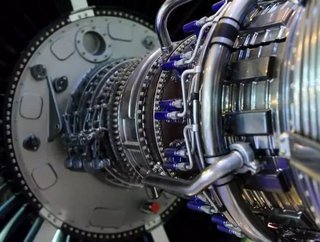

The UK government’s Industrial Strategy will fund four R&D projects within the aerospace industry with £24mn (US$34.17).

Each of the projects has been jointly funded and led by Rolls-Royce and will be taking place at its new engine test bed facility in Derby.

The funding aims to merge academia and businesses in the UK in order to develop new engine technologies for the aerospace sector.

One project will work towards X-Ray imaging – to be used to create faster and cleaner engines.

“Our modern Industrial Strategy is backed by the biggest increase in R&D investment this country has ever seen, committing government, along with industry, to spend £3.9bn to build on our reputation for aerospace excellence,” said Greg Clark, the UK’s Business Secretary.

“The joint government-industry funding brings together the best minds from Rolls-Royce, SMEs and academia to unlock breakthroughs in technology that are fundamental to the aerospace sector.”

SEE ALSO:

-

The Manufacturing Growth Programme has created more than 1,000 jobs in SMEs

-

Siemens invests in additive manufacturing technology for wind turbine production

“As the home of the first turbojet engine, the UK has a long proud heritage in aerospace and these pioneering Rolls-Royce projects will ensure it is the UK that leads the world in developing the next generation of cleaner jet engine technologies.”

The four projects in total are worth £58.3mn ($83mn) and are supported by the Aerospae Technology Institute and Rolls-Royce.

“We welcome the support announced by the UK Government today,” commented Chris Cholerton, President of Civil Aerospace at Rolls-Royce.

“These research projects will help Rolls-Royce and our partners develop more efficient, technologically sophisticated aircraft engines that are vital to reducing emissions and underline the aerospace industry’s commitment to improving the environment.”

“We are focused on pioneering new technologies and these projects will support important advancements for our UltraFan engine.”

“The UltraFan engine will offer a 25% fuel efficiency improvement over the first generation of Rolls-Royce Trent engines.”

- How Digital Twins are Transforming Product ManufacturingAI & Automation

- Aerospace Insight: Where does Boeing make all of its PlanesProduction & Operations

- GKN Aerospace’s Additive Manufacturing Technology ExpansionTechnology

- JPB Système: Aerospace challenges & sustainable processesSustainability & ESG