Mercedes-Benz digital factory campus to go live in 2022

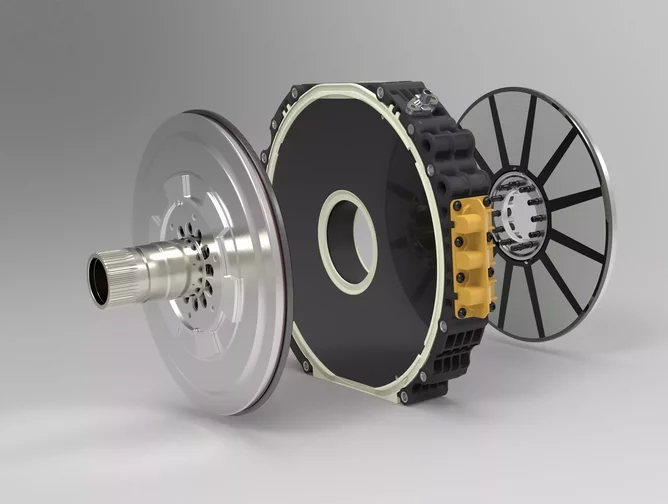

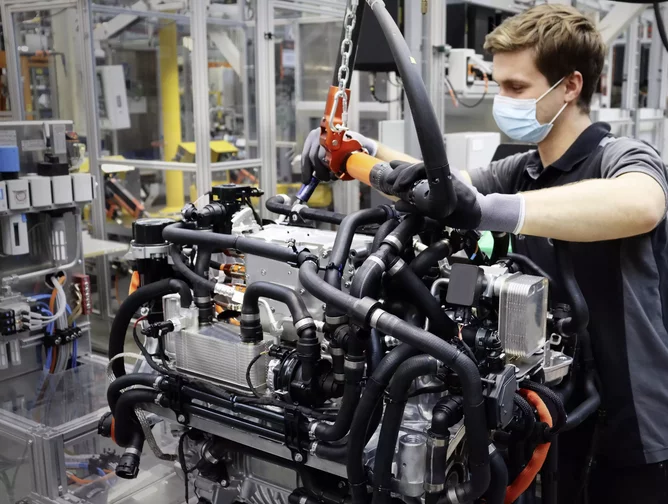

In an announcement made by Mercedes-Benz, the automotive manufacturer plans to build ultra-high-performance axial-flux electric motors at its manufacturing site in Berlin. The announcement forms part of the company’s strategy to go all-electric by 2030 (where market conditions allow).

Transforming the Berlin site will see Mercedes-Benz reach new digitalisation and electrification milestones as it furthers its future to sustainability and emissions-free. In addition, the company will further its product portfolio.

This latest announcement follows the company’s acquisition of YASA, a UK-based manufacturer of ultra0high-performance electric motors. With this acquisition, the manufacturer secured access to unique axial-flux production capabilities.

"The transformation of the automotive industry is more evident at our Berlin site than at any other Mercedes-Benz plant. The transformation from a production site for purely conventional drive components to a competence centre for digitalisation and production in the field of e-mobility is a significant step for us and our employees. We are offering groundbreaking new opportunities for this traditional location and underlining its role in our global production network - not least as a decisive driver of our digitalisation offensive. With the production of high-performance electric motors, the Berlin plant will become a key pillar of the sustainable Mercedes-Benz electrification strategy," said Jörg Burzer, Member of the Board of Management of Mercedes-Benz AG, Production and Supply Chain.

Mercedes-Benz Digital Factory Campus

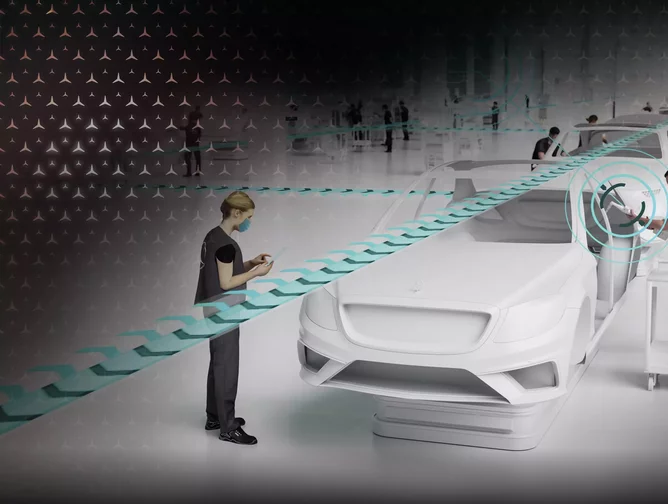

Built to develop, test, and implement pioneering MO360 software applications, Mercedes-Benz reports that its Mercedes-Benz Digital Factory Campus has reached an advanced stage.

Next year, the company plans to go live with a series of state-of-the-art pilot lines, making Berlin the competence centre for the brand’s global digitalisation of the production network. Berin will also support its worldwide rollout of new releases and apps in the MO360 ecosystem.

The Mercedes-Benz Digital Factory Campus will also become a training and qualification centre for MO360, with Mercedes-Benz investing a triple-digit million euros amount to transform the plant in the next six years.

"The transformation towards an electric and digital future is both a great challenge and a great opportunity. We will only master it by working together as a powerful Mercedes-Benz team. The shift to electric mobility will change tasks and employment profiles. Our goal is to shape this change for the employees in a responsible, socially acceptable and future-oriented manner,” said Sabine Kohleisen, Member of the Board of Management of Mercedes-Benz AG, responsible for Human Resources and Labour.

“We are overwhelmed by the level of acceptance on the part of employees for the digital transformation of this Mercedes-Benz site Berlin. The huge interest in our digital qualification offerings demonstrates to us that we are on the right path. Employees are ready to take on a new challenge. A big thank you to the staff, and the works council, for embarking on this path with us,” added Kohleisen.

"Securing the sustainable future of our Mercedes-Benz site in Berlin has always been at the forefront of our minds. With the transformation of the site into a digital factory campus and competence centre for high-performance electric motors, we have taken a decisive step towards the future for our oldest production site. Together with the site manager, Clemenz Dobrawa, we have opened the door to the future. Thus, a successful transformation can begin with and for the employees,” concluded Michael Rahmel, Chairman of the Works Council Mercedes-Benz Plant Berlin.

- Crowe UK: 2024 Manufacturing Outlook Report Explores GrowthProduction & Operations

- Top 10: Chief Manufacturing OfficersProduction & Operations

- Aerospace Insight: Where does Boeing make all of its PlanesProduction & Operations

- Comau's Automation Solutions for Outside of ManufacturingAI & Automation