Nexans Colombia

Produced by Diego Pesantez

The journey from CEDSA’s beginnings as a family business, having been part of MADECO, to finally joining Nexans’ global subsidiary network, provides the company with the corporation’s experience and advantages, strengthening its presence by having a market share of 15 percent.

“The corporation has supported us relentlessly; we have access to the same kind of technology as the rest of affiliates worldwide, even though Nexans is practically a new brand in the domestic market. Also, in just a few years we experienced the transition from a family-run enterprise into a global operation,” Silva added.

Value Chain and Suppliers’ Role

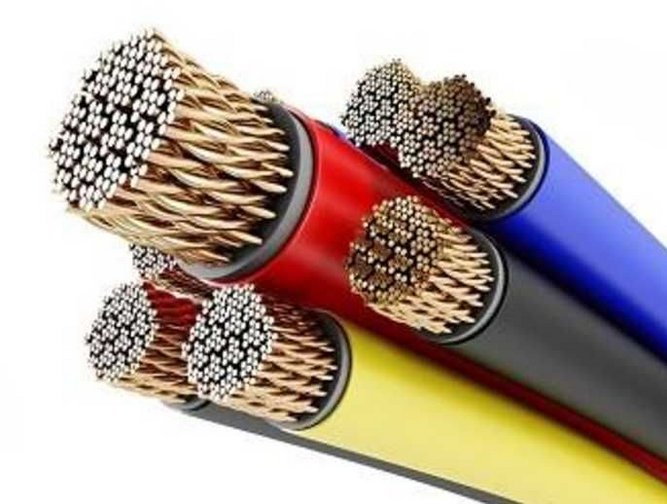

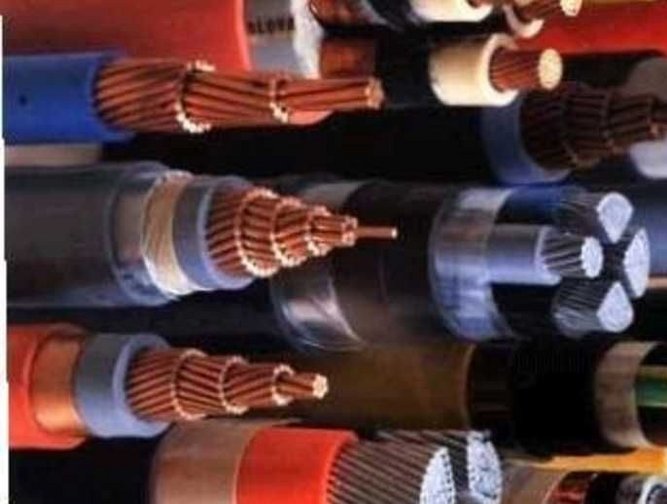

The procurement and logistics department is in charge of a vast array of operations from obtaining raw material up to product distribution. The company operates based in the brand’s global value chain, striving to secure the best materials and procedures available; for example, logistics obtains from Chile and Peru’s subsidiaries, the highest quality copper for cable production.

“Suppliers play a very important role in the company’s value chain; some of them are vital for us from obtaining raw material up to waste management, with packaging and freights worth mentioning, too,” Silva remarked.

Current Operations

Clients receive Nexans’ products through construction contractors and utilities, which means brand placement focuses on these two entities. As a result, Nexans Colombia has earned several contracts with the Group EMP and in projects with a bi-yearly cost of more than $20 million in the last six years, including works with Pacific Rubiales, Ecopetrol, CODENSA group and others.

Automation has played a big part in Nexans Colombia’s procedures by raising productivity and lowering costs through “Direct Machine Control” software.

“Converting into Nexans’ global culture demands an upgrade in every process for a client-centered business frame,” pointed the company’s CEO.

HR Management Resulting in Leadership

The Nexans Excellent Way program considers every procedure in their global value chain. The trade’s best practices and leadership are permanent goals for the program, as well as making employee safety a top priority. The strict observance of these principles resulted in zero labor accidents during 2013.

“Continuous improvement has a presence in just about every area in the company. Our purpose is for each individual to be proactive within their position’s development,” Silva said.

Forecast: Sights on Domestic Growth

The company’s plans for the near future include an aggressive approach to the domestic market. Set goals for 2015 and 2017 are 15 and 17 percent growth, respectively, with an aim to become the country’s second largest company within the industry.

In order to achieve this goal, Nexans Colombia will expand its catalogue, provide a full line of products for all of their clients’ requirements and introduce halogen-free and flexible cables.